Introducing the accroma SamplePrep System

Sample IN – Answer OUT for chemical analysis of solid and semi-solid samples.

Automated sample preparation for more trustworthy results and a more productive lab.

We Enable Quick Automation without Sacrificing Flexibility.

We use cookies and similar technologies on our website and process personal data (e.g. your IP address) about you. We also share this data with third parties. Data processing can take place with your consent or on the basis of a legitimate interest, which you can object to in the individual privacy settings. You have the right to only consent to essential services and to change or revoke your consent in the data protection declaration at a later date.

Einige Services verarbeiten personenbezogene Daten in unsicheren Drittländern. Indem Sie in die Nutzung dieser Services einwilligen, erklären Sie sich auch mit der Verarbeitung Ihrer Daten in diesen unsicheren Drittländern gemäß Art. 49 Abs. 1 lit. a DSGVO und Art. 17 Abs. 1 lit. a DSG (Schweiz) einverstanden. Dies birgt das Risiko, dass Ihre Daten von Behörden zu Kontroll- und Überwachungszwecken verarbeitet werden, möglicherweise ohne die Möglichkeit eines Rechtsbehelfs.

If you load the blocked content, your privacy settings will be adjusted. Content from this service will no longer be blocked in the future. You have the right to withdraw or change your decision at any time.

Why Should you Automate your Sample Preparation Workflows?

Manual sample preparation of solid and semi-solid samples is a highly inefficient process and reliable automation has been an unsolved problem. Time and solvent-intensive cleaning steps due to carryover problems were just one of the challenges.

Reduced Costs

by saving commercial space and using resources smart.

Superior Accuracy and Precision

by minimizing human errors and -variability

Improved Efficiency

by full process automation, simplified method transfer while reducing cycle- and hands-on time.

Improved Compliance

by reducing deviations and getting traceable documentation.

Safer Workspace

Reduction of exposure to toxic substances and no glassware.

«Accromated sample preparation delivers more trustworthy results, improves traceability while increasing productivity and safety.»

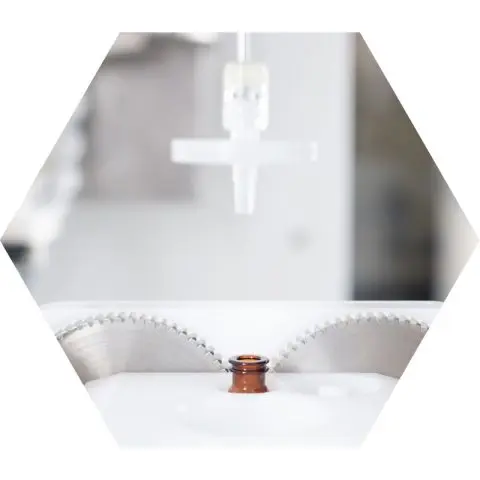

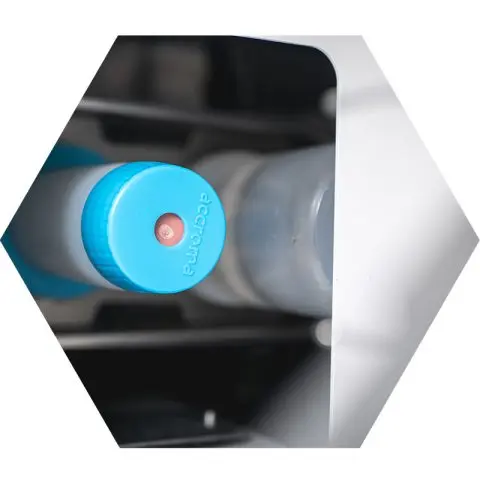

The accroTube – a Gamechanger

Each sample is prepared in its own disposable and closed tube which avoids evaporation, sample loss and carry over. This makes your workflows flexible, fast and reproducible.

Step 1

Sample Introduction

Introduce your sample and potential milling and / or mixing aids

Step 2

Grinding

Samples can be dry or wet milled by a very strong vertical shaking, like in a ball mill

Step 3

Liquid Handling

Solvents are introduced or transferred through the septum to perform solvent addition, pipetting, dilution, or phase separating steps

Step 4

Extraction

Extraction is performed with a very effective shaker or by ultra sonication

Step 5

Filtration

Sample solutions are automatically filtered directly into HPLC vial. Vials are capped and may be transferred directly into the analyser.Note: this is just a very basic example workflow, you have no limit in terms of numbers of steps and you are free in the order of the individual steps – discuss your methods directly with us.

The accroTube – a Gamechanger

Each sample is prepared in its own disposable and closed tube which avoids evaporation, sample loss and carry over. This makes your workflows flexible, fast and reproducible.

Step 1

Sample Introduction

Introduce your sample and potential milling and / or mixing aids

Step 2

Grinding

Samples can be dry or wet milled by a very strong vertical shaking, like in a ball mill

Step 3

Liquid Handling

Solvents are introduced or transferred through the septum to perform solvent addition, pipetting, dilution, or phase separating steps

Step 4

Extraction

Extraction is performed with a very effective shaker or by ultra sonication

Step 5

Filtration

Sample solutions are automatically filtered directly into HPLC vial. Vials are capped and may be transferred directly into the analyser.Note: this is just a very basic example workflow, you have no limit in terms of numbers of steps and you are free in the order of the individual steps – discuss your methods directly with us.

Traditional Sample Preparation Techniques Need to Change

Many laboratories have identified sample preparation as most frustrating and expensive component of sample analysis. While analytical technology has evolved remarkably over the last two decades, most sample preparation still relies on antiquated manual techniques. Even the simplest methods can produce unreliable results and highly variable reproducibility.

61%

of an analyst’s time is dedicated to sample preparation and its documentation.

90%

of all Out of Specification (OOS) results are not quality related but are caused during the analytical procedures.

More than 30%

of all errors occur during sample preparation.

The only solution to optimize such inefficient, error-prone, and expensive processes is automation. It leads to standardized and digitalized sample preparation for lean labs 4.0.

One Innovation – Three Major Advantages

Reproducibility

The close and dispoable tubes impede evaporation and carry-over for reproducible and reliable results.

Flexibility

Switching between samples is simple. Up to 64 different samples, each with a different workflow can be prepared in one run.

Speed

Vertical shaking enables quick grinding and extraction. Workflows can be overlapped for maximum throughput and as no cleaning is required, cycle times are short.

Sample Volume

The accroTube technology makes the accroma system suitable even for laboratories with low and diverse sample volumes. We automate your sample preparation without sacrificing flexibility.

Method Transfer is Simple

The automation of manual sample preparation method may not require any adjustments. If a method needs to be modified for automation, there is a simple and defined process to proof equivalence.

Your Tubes are Sustainable

To ensure scientific accuracy and reproducibility, accroma requires material of highest quality and inertness. Sustainability is important to us for which reason we use recyclable materials like polyethylene and iron. Both materials are 100% recyclable and can be reused as secondary raw materials. However, we need your help to separate content, tubes and steel balls.

Large sample type compatibility

The volume range of the accroTubes and the functionalities of the system allow to automate the sample preparation of a wide range of sample types. Therefore, it is used in numerous industries for the preparation of samples for chemical analysis. Whether it is the determination of Active Pharmaceutical Ingredients in tablets or contaminants in food, we offer sample IN – Answer OUT automation.

Easy Transfer of your Methods to Automation

Step 1

Sample Introduction

Introduce your sample and potential milling and / or mixing aids

Step 2

Grinding

Samples can be dry or wet milled by a very strong vertical shaking, like in a ball mill

Step 3

Liquid Handling

Solvents are introduced or transferred through the septum to perform solvent addition, pipetting, dilution, or phase separating steps

Step 4

Extraction

Extraction is performed with a very effective shaker or by ultra sonication

Step 5

Filtration

Sample solutions are automatically filtered directly into HPLC vial. Vials are capped and may be transferred directly into the analyser.Note: this is just a very basic example workflow, you have no limit in terms of numbers of steps and you are free in the order of the individual steps – discuss your methods directly with us.

The accroma System

Reduce expensive lab space by condense most functionalities on a small footprint. The accroma does not require lab infrastructure and can operate 24/7 in normal commercial space with electricity.

#1 Rack

The rack of the accroma system is incorporated into the door for optimal access and has 124 positions. It can hold multiple formats like sample- and dilution tubes, centrifuge counterweights and tubes containing reagents for dispersive solid phase extraction (dSPE). To maximize flexibility, additional solvents and filter types can be placed on the rack as well.

#2 Shaker

The shaker accelerates accroTubes vertically with a standardized frequency and amplitude. By shaking the tube either milling or extraction can be performed. By adding one or multiple milling aids like a steel ball into a tube turns the shaker into a ball bill but without sample loss. Even the hardest samples can be grinded by the powerful shaking. If solvent is added to the tube prior shaking, the process is called wet milling or homogenization, which combines milling and extraction into one step.

#3 Analytical Balance

The rack of the accroma system is incorporated into the door for optimal access and has 124 positions. It can hold multiple formats like sample- and dilution tubes, centrifuge counterweights and tubes containing reagents for dispersive solid phase extraction (dSPE). To maximize flexibility, additional solvents and filter types can be placed on the rack as well.

samples and solvents

#4 Liquid module

The liquid module has two needles, each connected to a dedicated pump and solvent bottle. Liquids can be added to a tube by dispensing from a solvent bottle or by pipetting from another tube. Pipetting is used for dilution, phase separation, insertion of standards or for additional solvent lines. The needles have a liquid level detection functionality. Therefore, the needles can collect liquids in a defined immersion depth.

functionality

volumes

#5 Ultrasonic bath – optional

Ultrasonication is an alternative extraction technique, which can be added to a system. It is a tool to simplify method transfers and facilitate extraction for challenging samples. It includes a Tube drying station to avoid weighing errors.

#6 Centrifuge – optional

The centrifuge is an optional clean-up module used for separation of compounds with different densities. The maximum rotation speed is 4600 rpm, which corresponds to a G-force of 4250 RCF. It is the only module in the accroma that is temperature controlled (-10 – 40°C)

#7 Online Analysis interface – optional

Do you want to avoid manual vial transfer to analyzers and get results as soon as possible? Then connect the accroma sample preparation system to a (U)HPLC / UPLC system from Agilent Technologies or Waters Corporation. We offer standardized interfaces to exchange the prepared vials for online injection. After injection, the vials are parked in the accroma system and remain available for potential reinjection. a

– Software Interfaces

– high precision

– no sample loss

– hardware interfaces

Intuition Redefined

Ease of Use

It really is this simple:

1. Create a workflow

2. Prepare consumables

3. Assign workflow to one or multiple samples and start.

Your samples will be prepared unsupervised.

Security

The accroLab software was designed to meet latest security and compliance requirements. Data integrity, Audit Trail and electronic signatures were incorporated to equip you for GMP/GLP work.

Interfaces

Setup your sequence table in accroLab, which will control Empower 3 or Chromeleon to start injections. Relevant sample preparation data will be transferred to your CDS and LIMS.

Your Tubes are Sustainable on the Second Look

Reusable containments like glass for example are per se not more sustainable than disposables. Cleaning requires solvents/water, detergents and energy that needs to be taken into account. Furthermore, manual sample preparation often requires disposable pipettes and personal protection items.

To ensure scientific accuracy and reproducibility, accroma requires material of highest quality and inertness. Sustainability is important to us for which reason we use recyclable materials like polyethylene and iron. Both materials are 100% recyclable and can be reused as secondary raw materials. However, we need your help to separate content, tubes and steel balls.

Join the Future

Experts and laboratory specialists agree that the laboratory of the future is completely automated and digitized. However, this is easier said than done. Automating sample preparation of solid and semi-solid samples is challenging and was one of the missing pieces to make the Lab 4.0 possible. Other efforts are aimed at bringing the lab in a box directly to the process to enable real time release.