About Us

Pioneers for Laboratory 4.0

We are an innovative company, founded in 2014, and passionately dedicated to revolutionizing sample preparation for quality control. Our home is the GETEC Industry Park in Muttenz, near the life science hub of Basel. From here, we develop forward-looking solutions to transform today's laboratory into a fully automated and digitized Laboratory 4.0.

Our Strength: Interdisciplinary Expertise

Our success is built upon a diverse team of highly qualified experts. We unite core competencies from various specialized fields to create comprehensive and high-performance systems:

- Mechanical Engineers

- Software Engineers

- Chemists & Chemical Engineers

Our Mission & Vision

Mission: We are innovating and revolutionizing sample and eluent preparation for quality control. Our goal is to deliver groundbreaking technologies that fundamentally change the way laboratories operate.

Vision: We are the pioneers for a fully automated and digitized Laboratory 4.0, where manual bottlenecks are a thing of the past.

What We Achieve for Our Customers

With our solutions, we support our customers in significantly improving their laboratory processes and overcoming critical challenges. We help you to achieve the following goals:

- Obtain More Reliable Results: By standardizing and automating manual work, we minimize human errors and increase precision.

- Overcome Bottlenecks: We eliminate the most time-consuming and tedious steps in sample and eluent preparation, thus freeing up capacity.

- Improve Productivity: Through automation and digitalization, we increase throughput and optimize efficiency.

- Comply with Increasing Regulatory Requirements: Our documented and controlled processes ensure compliance with strict regulatory standards.

History

Sustainability

We care about our planet and want to reduce environmental problems. We all can do our part, which ultimately will add up to a significant change to sustainability.

Our mission is to create circular economies for all our products and manage resources for our services efficiently and smart. We are constantly reviewing and optimizing our carbon footprint in life cycle assessments with the ultimate goal to achieve Net zero greenhouse gas emissions.

System

accroma is supplied by local suppliers prior final production and testing of the products in Switzerland. When selecting suppliers, we consider working conditions, the origin of raw materials and the sustainability of manufacturing.

We set the highest standards for the quality of system components and design the accroma system for backwards compatibility so that modules can also be retrofitted. Furthermore, it paves the way for our system refurbishment program, which leads to an extension of the product life cycle and thus to less disposal.

Consumables

Reusable containments like glass for example are per se not more sustainable than disposables. Cleaning requires solvents/water, detergents and energy that needs to be considered. Furthermore, manual sample preparation often requires disposable pipettes and personal protection items.

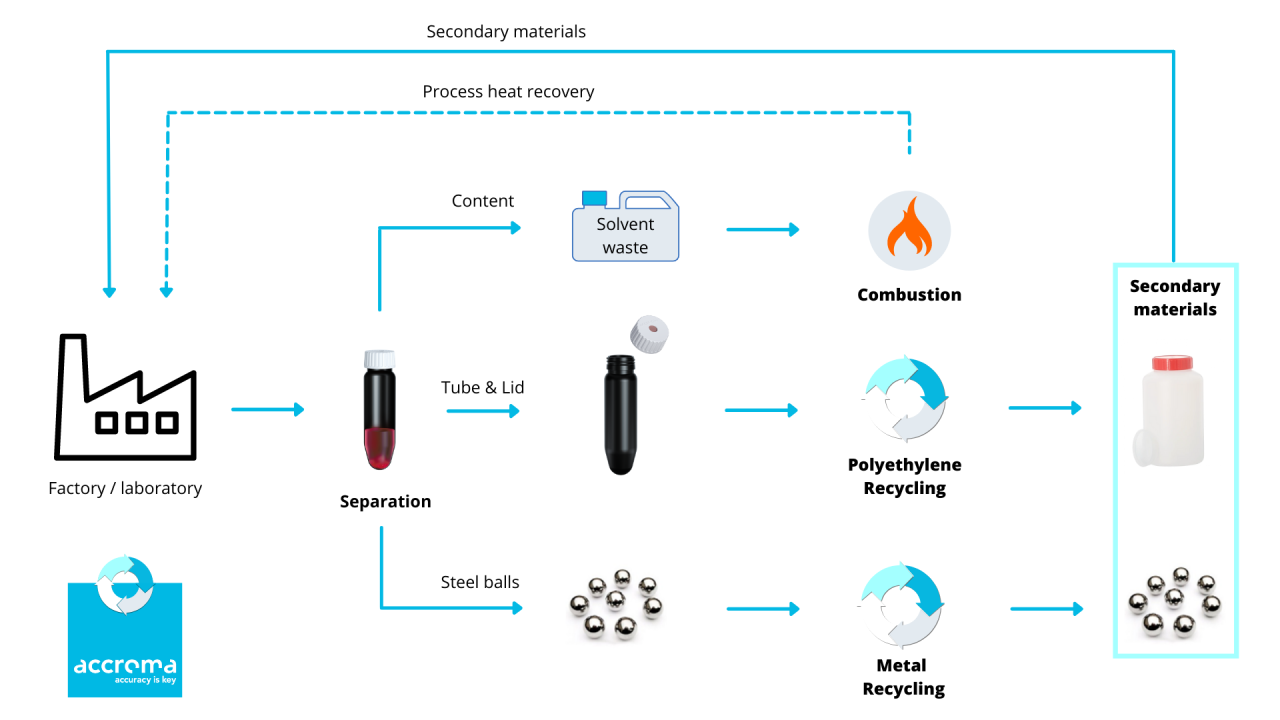

To ensure scientific accuracy and reproducibility, accroma requires material of highest quality and inertness. Sustainability is important to us for which reason we use recyclable materials like polyethylene and iron. Both materials are 100% recyclable and can be reused as secondary raw materials. However, we need your help to separate content, tubes and steel balls if reopening the tubes is reasonable in terms of toxicity. We recommend the following material and energy recycling strategy:

Services

Our service providers are selected based on response times and distances to our users. Furthermore, our pre-sales and remote services (hotline & software remote access) are designed to avoid unnecessary travelling and reduce our carbon footprint.

Compliance

accroma labtec Ltd. respects applicable law, including international laws, and requires all of its employees and business partners to do the same.

The following are some of the key points that are of particular importance:

Employee relations and rules

Information management

Supplier, dealer and service relationships

Competitor relationships and competition

Participation in events

Confidentiality

Customer gifts

Join the Future

Experts and laboratory specialists agree that the laboratory of the future is completely automated and digitized. However, this is easier said than done. Automating sample preparation of solid and semi-solid samples is challenging and was one of the missing pieces to make the Lab 4.0 possible. Other efforts are aimed at bringing the lab in a box directly to the process to enable real time release.